Exploring the Basics of Wire Mesh

Introduction

At California Wire Products, we’re truly passionate about the remarkable potential of wire meshes, and we can’t wait to embark on this journey of exploration with you. These wire meshes are, in many ways, the unsung heroes behind the scenes of numerous industries, working diligently and quietly to fulfill vital functions. In the upcoming pages of this blog, our aim is to pull back the curtain and reveal the captivating world of wire meshes, leaving no stone unturned. From the very fundamentals of what wire meshes are to the intricacies of wire mesh specifications, we’re here to guide you through it all. We understand that wire meshes can seem like a well-kept secret, and it’s our pleasure to demystify this versatile material for you. Whether you’re just starting out, eager to grasp the basics, or you’re a seasoned professional seeking to deepen your understanding, we’ve designed this guide to cater to all levels of expertise. Our hope is that, by the end of this journey, you’ll emerge with a newfound appreciation for the incredible versatility and importance of wire meshes in various industries. So, let’s dive into the world of wire meshes, exploring their composition, the science behind their specifications, and the real-world applications that showcase their significance. Together, we’ll illuminate the path to a better understanding of wire meshes, and we’re thrilled to have you along for the ride. Is this conversation helpful so far?What is Wire Mesh?

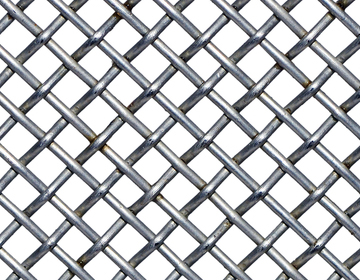

Let’s begin our exploration by delving into the very essence of wire mesh. At its core, wire mesh is a marvel of simplicity and ingenuity. It’s a material crafted by interweaving or welding wires together, meticulously fashioning a grid-like pattern that is both sturdy and flexible. While this description may make it sound unassuming, the truth is that wire mesh possesses a remarkable versatility that is nothing short of awe-inspiring. Imagine a meshed network of wires, each strand meticulously placed to create a harmonious structure. This grid, although seemingly straightforward, becomes a foundation for a world of innovation and problem-solving across various industries. The beauty of wire mesh lies not only in its composition but in its ability to adapt and serve an astonishing array of functions. As we journey deeper into the realm of wire mesh, we’ll uncover its diverse applications, from reinforcing concrete structures in construction to providing security as fencing in agriculture. We’ll also unravel the intricate science behind wire mesh specifications, such as wire gauge and opening size, and how these seemingly small details can have a profound impact on its performance. If you are in Corona, CA and in need of wire mesh, note that, we at California Wire Products are here to meet your local needs. Keep reading to learn more about the different types of wire mesh.Types of Wire Mesh

There are two primary types of wire meshes, each with its own set of features that make it suitable for various purposes.Woven Wire Mesh

Woven wire meshes are created by weaving wires together, resulting in a flexible and robust material. These versatile meshes find their way into a myriad of applications. In construction, wire meshes from California Wire Products are frequently used to reinforce concrete structures, ensuring buildings stand strong for years to come. In agriculture, they serve as reliable fencing for livestock and offer support for crops, such as climbing vegetables.

In construction, wire meshes from California Wire Products are frequently used to reinforce concrete structures, ensuring buildings stand strong for years to come. In agriculture, they serve as reliable fencing for livestock and offer support for crops, such as climbing vegetables.

Welded Wire Mesh

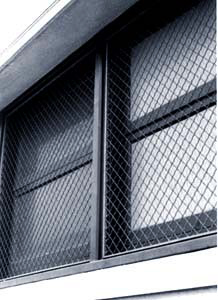

On the other hand, welded wire meshes are constructed by welding individual wires at their intersections, creating a rigid and sturdy structure. This type of mesh excels in applications where strength and stability are paramount. For example, in construction, wire mesh grades are crucial for creating concrete reinforcement grids that can withstand heavy loads. They also shine as fencing material, providing security and durability in various settings.

Wire Mesh Specifications: Unraveling the Details

Now that we’ve familiarized ourselves with the fundamental nature of wire mesh, it’s time to embark on a journey into the intricate world of wire mesh specifications. These specifications are the secret codes that determine how wire meshes perform in various applications, and they play a pivotal role in making the right choice for your specific needs.Wire Gauge: Measuring Strength and Durability

Among the key wire mesh specifications, wire gauge stands out as a critical factor in determining the mesh’s overall robustness. Wire gauge essentially refers to the thickness of the wires used to construct the mesh. Think of it as the wire’s “size” within the mesh. This seemingly simple number has a profound impact on the mesh’s strength and durability. A higher gauge number indicates a thinner wire, while a lower gauge number means a thicker wire. The choice of wire gauge can make all the difference in applications ranging from construction to industrial filtration. In essence, wire gauge is the backbone of your wire mesh. Choosing the appropriate gauge ensures that your wire mesh can withstand the forces it’ll encounter in its intended environment. It’s the difference between a mesh that’s up to the task and one that might fall short.Opening Size: The Filter’s Gatekeeper

Another crucial element in wire mesh specification is the opening size. Picture the wire mesh as a gatekeeper, and the opening size as the gates themselves. These openings determine what can pass through the mesh and what gets stopped in its tracks. The opening size specification holds particular significance in filtration applications, where precision matters most. In industries like water and air filtration, getting the opening size just right can mean the difference between effective filtration and letting unwanted particles through. Imagine a water filtration system. If the openings in the wire mesh are too large, it might fail to capture smaller impurities, rendering the filtration process less effective. Conversely, if the openings are too small, it could impede the flow of water, causing inefficiencies. In summary, opening size is the gatekeeper of your wire mesh, regulating what can pass through while maintaining optimal performance. It’s a specification of paramount importance, especially in applications where purity and precision are non-negotiable. Understanding wire mesh specifications like wire gauge and opening size is like deciphering the language of wire meshes. It allows you to select the right mesh for the job, ensuring that it performs optimally and meets your specific requirements. So, as we continue our exploration of wire meshes, keep these specifications in mind, for they are the keys to unlocking the full potential of this remarkable material.Real-World Application

Now, let’s dive into some real-world applications that showcase the versatility of wire meshes. In the automotive and manufacturing sector, wire mesh grades from California Wire Products are commonly found in automotive grilles and radiator screens, where they offer both protection and style. Additionally, they play a pivotal role in conveyor belt systems, ensuring efficient material handling and production. Conclusion

Conclusion

California Wire Products: Your Trusted Partner in Wire Mesh Solutions

For over seven decades, California Wire Products has been a steadfast leader in the manufacturing of woven wire mesh partitions, handrail panels, security cages, and storage lockers. Since our establishment in 1948, we’ve made it our mission to provide top-notch wire mesh solutions that cater to a wide range of security requirements and access control needs. Our commitment to excellence shines through in our versatile and effective modular systems. These systems have been designed with your unique security challenges in mind, offering tailored and ready-to-go options that seamlessly adapt to your specific requirements. Whether you’re looking to safeguard valuable assets, control access to restricted areas, or optimize storage space, California Wire Products has you covered. Our wire meshes are the backbone of these security solutions, and they’ve proven their worth across various industries. Thanks to their exceptional characteristics and diverse applications, our wire meshes have become indispensable components in fields like construction, agriculture, and filtration. Understanding the nuances of wire meshes, including the various types and critical specifications, is key to making the right choices for your unique needs. Whether you’re a seasoned professional or just beginning to explore the possibilities of wire meshes, our team at California Wire Products is here to assist you every step of the way. At California Wire Products, we’re not just a manufacturer; we’re your partner on the journey of discovery. Don’t hesitate to call us at 951-371-7730 for more information and to explore the endless opportunities that wire meshes bring to your industry and projects. We look forward to helping you achieve your security and access control goals with the finest wire mesh solutions available. FAQs- Q: What are the different types of wire mesh and their applications? A: Wire mesh comes in two primary types: woven and welded. Woven wire mesh is flexible and commonly used in construction and agriculture, while welded wire mesh offers strength and stability, making it ideal for applications like concrete reinforcement and fencing.

- Q: How do wire mesh specifications like wire gauge and opening size affect its performance? A: Wire gauge determines the thickness of the wires in the mesh, impacting its strength. A lower gauge number means thicker wires, suitable for heavy-duty applications. Opening size dictates what particles can pass through the mesh; it’s crucial for effective filtration, ensuring only desired materials get through.

- Q: Can you provide examples of real-world applications for wire mesh in construction and filtration? A: Certainly! In construction, wire mesh reinforces concrete structures, ensuring their durability. In filtration, wire mesh is used in water and air filtration systems, allowing for precise particle separation. These are just a few examples of wire mesh’s diverse applications across industries.

GET IN TOUCH

Contact us today to place your wire mesh order!