Enhancing Workplace Safety with Mesh Gas Cylinder Cages

Introduction

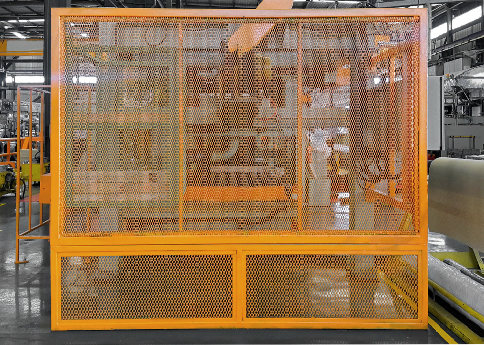

Ensuring workplace safety is a top priority for businesses across all industries. One critical aspect of this is the proper storage of gas cylinders, which, if mishandled, can pose significant hazards. Improper storage can lead to severe accidents, including explosions, fires, and toxic gas leaks. This is where mesh gas cylinder cages from companies like California Wire Products come into play. Primarily designed for warehouses, offices, and factories, these cages mitigate the risks associated with gas cylinder storage, providing a safe and secure environment for these potentially dangerous items. Keep reading to learn more about one of the most crucial types of warehouse storage cages, the wire mesh gas cylinder cage.Section 1: Understanding the Risks

Gas cylinders are ubiquitous in many workplaces, used to store a variety of gases such as oxygen, acetylene, propane, and nitrogen. Each type of gas cylinder comes with its own set of potential hazards:- Flammable gases (e.g., propane, acetylene): These can cause fires or explosions if they leak and come into contact with an ignition source.

- Toxic gases (e.g., chlorine, ammonia): These can pose serious health risks if they are released into the workplace environment.

- Oxidizers (e.g., oxygen): These can intensify fires and are hazardous if they leak near flammable materials.

Section 2: The Basics of Mesh Gas Cylinder Cages

Mesh gas cylinder cages, one of the most important types of warehouse storage cages, offer specialized storage solutions as they are designed to hold gas cylinders securely. These cages are constructed with a mesh design that provides several key features:-

Ventilation

-

Visibility

-

Durability

Section 3: Legal and Regulatory Requirements

The storage of gas cylinders is governed by various legal and regulatory frameworks to ensure workplace safety. In the United States, the Occupational Safety and Health Administration (OSHA) sets stringent guidelines for gas cylinder storage. Key regulations include:- Proper labeling and identification of gas cylinders.

- Secure storage to prevent cylinders from falling or being knocked over.

- Adequate ventilation to prevent the accumulation of flammable or toxic gases.

Section 4: Benefits of Using Mesh Gas Cylinder Cages

Using mesh gas cylinder cages offers numerous benefits that enhance workplace safety and efficiency:-

Enhanced Safety

-

Improved Organization

-

Regulatory Compliance

-

Theft and Unauthorized Access Protection

Section 5: Selecting the Right Mesh Gas Cylinder Cage

Choosing the right mesh gas cylinder cage depends on various factors, including the types of gas cylinders being stored and the specific needs of the workplace. Consider the following when selecting a cage:-

Size and Capacity

-

Location

-

Safety Features

Section 6: Best Practices for Installation and Maintenance

Proper installation and maintenance of mesh gas cylinder cages are essential for ensuring their effectiveness:-

Installation Tips

- Place the cage on a flat, stable surface to prevent tipping.

- Ensure it is in a well-ventilated area away from potential ignition sources.

- Secure the cage to the floor or wall if necessary to prevent movement.

-

Maintenance Tips

- Regularly inspect the cage for signs of damage or wear.

- Check the integrity of the locks and hinges.

- Ensure the ventilation is not obstructed.

Conclusion

Mesh gas cylinder cages play a critical role in ensuring workplace safety by providing secure and compliant storage for gas cylinders. Businesses should evaluate their current storage solutions, including the use of warehouse storage cages, and consider adopting mesh gas cylinder cages from companies like California Wire Products to enhance safety, organization, and regulatory compliance. By doing so, they can protect their employees, reduce the risk of accidents, and avoid legal and financial repercussions. Prioritizing the proper storage of gas cylinders is a vital step toward creating a safer work environment for everyone. Call us at (951) 371-7730 for more information.FAQs

1. How do mesh gas cylinder cages contribute to workplace safety? A: Mesh gas cylinder cages provide secure storage for gas cylinders, minimizing the risk of tipping and leaks. The mesh design ensures proper ventilation, reducing the buildup of hazardous gases. Additionally, these cages make it easy to perform visual inspections, helping to identify potential issues before they become serious hazards. 2. What factors should be considered when installing a mesh gas cylinder cage? A: When installing a mesh gas cylinder cage, consider placing it on a flat, stable surface to prevent tipping. Ensure the cage is in a well-ventilated area away from ignition sources. For added security, you might also want to secure the cage to the floor or wall to prevent any movement. 3. Why is regular maintenance of mesh gas cylinder cages important? A: Regular maintenance of mesh gas cylinder cages is crucial to ensuring ongoing safety and compliance. Routine inspections can help identify signs of wear or damage, ensuring the cage’s integrity. This proactive approach helps prevent accidents and maintain a safe storage environment for gas cylinders.GET IN TOUCH

Contact us today to place your wire mesh order!