Introduction

Stainless steel welded wire mesh is a versatile and durable material used in various industries for its strength, corrosion resistance, and adaptability. Whether for security fencing, construction reinforcement, or filtration systems, this welded wire mesh is a go-to choice for projects that require reliability and longevity. In this blog, we’ll explore the key benefits, common uses, and important factors to consider when choosing this mesh for your project. California Wire Products provides high-quality wire mesh for various applications.

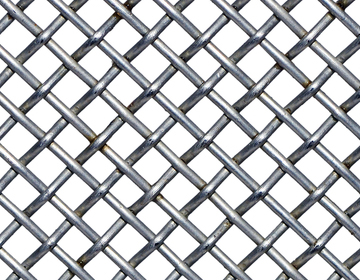

What is Stainless Steel Welded Wire Mesh?

It is created by welding intersecting steel wires at every junction, forming a strong and durable grid. Various types of stainless steel are used, such as 304 and 316, each offering specific benefits depending on the application. The manufacturing process involves advanced welding techniques that ensure the mesh’s strength and uniformity. California Wire Products ensures that every piece of stainless steel welded wire meets the highest quality standards, with stringent quality control measures in place.

Benefits of Using Stainless Steel Welded Wire Mesh

There are numerous advantages to using this welded wire mesh in your projects:

- Durability and Strength: The robust design of stainless steel welded wire panels makes them ideal for heavy-duty industrial and commercial applications.

- Corrosion Resistance: Stainless steel’s resistance to rust and environmental damage ensures the long life of products, even in harsh conditions.

- Versatility: Whether you’re looking for fencing solutions, filtration systems, or reinforcement for construction, this welded wire offers flexibility across many applications.

- Aesthetic Appeal: This mesh not only serves a functional purpose but also offers a modern, sleek appearance for architectural and decorative uses.

Applications of Stainless Steel Welded Wire Mesh

The versatility of stainless steel welded wire mesh allows it to be utilized across a wide range of industries:

- Industrial Applications: It’s widely used for added strength in filtration, security cages, and construction reinforcement.

- Commercial Uses: Steel welded wire panels are ideal for fencing, partitions, and architectural designs, offering both functionality and style.

- Marine and Aquatic Applications: Due to its corrosion resistance, this welded wire mesh is perfect for use in marine environments, including dock barriers and aquaculture.

Factors to Consider When Choosing Stainless Steel Welded Wire Mesh

Selecting the right stainless welded wire mesh for your project involves considering a few key factors:

- Mesh Size and Aperture: The mesh size should be tailored to your specific application, such as filtration or security.

- Wire Diameter and Gauge: Thicker wire increases strength, while thinner wires provide more flexibility.

- Stainless Steel Grade: Higher-grade stainless steel like 316 is recommended for corrosive environments.

- Coatings and Finishes: Additional coatings may enhance durability or provide a different aesthetic look.

Installation and Maintenance Tips

Proper installation and maintenance of stainless steel welded wire mesh are crucial to maximizing its lifespan:

- Installation Techniques: Use appropriate fastening tools and methods to secure the mesh. Ensure that it is tensioned properly to prevent sagging.

- Tools and Equipment: Basic tools such as cutting devices, welding equipment, and fastening tools are necessary for installation.

- Routine Maintenance: Regular cleaning, using water or mild detergents, can keep stainless steel welded wire looking new and prevent debris buildup.

- Common Issues: Regular inspections are recommended to identify any wear, tear, or sagging, which can be addressed quickly to maintain performance.

Environmental and Sustainability Considerations

Stainless welded wire mesh is not only durable but also environmentally friendly:

- Recyclability: Stainless steel is 100% recyclable, which reduces waste and environmental impact.

- Environmental Impact: Manufacturers like California Wire Products are implementing sustainable practices in production, reducing energy consumption and emissions.

- Sustainable Practices: This welded wire mesh is a long-lasting solution, minimizing the need for frequent replacements and conserving resources over time.

Conclusion

Stainless steel welded wire mesh offers unmatched strength, versatility, and corrosion resistance, making it an ideal solution for various industrial, commercial, and marine applications. Whether you need durable fencing, security cages, or architectural panels, this welded wire mesh delivers superior performance and sustainability. California Wire Products provides a wide range of high-quality welded wire products to meet your needs. For more information or to explore our product range, contact us today! Call us at (951) 371-7730 for more information.

FAQs

1. What are the key differences between stainless steel welded wire mesh and other wire mesh materials?

A: Stainless steel welded wire mesh stands out due to its superior corrosion resistance, making it ideal for harsh environments, unlike other materials like galvanized steel, which may require coatings or treatments to resist rust. Additionally, stainless steel offers a cleaner, more polished finish for aesthetic purposes.

2. How does stainless steel welded wire mesh contribute to safety in construction?

A: Stainless steel welded wire mesh provides structural reinforcement in concrete and other building materials, enhancing the safety and stability of construction projects. It also plays a key role in security applications, such as protective barriers and safety cages, ensuring reliable protection against intrusions.

3. Can stainless steel welded wire mesh be customized for specific project needs?

A: Yes, stainless steel welded wire mesh can be customized in terms of mesh size, wire diameter, and even shape to meet the unique requirements of different projects, from architectural designs to industrial filtration systems. This flexibility makes it a go-to material for tailored solutions.