The Mesh Debate: Wire vs. Fiber in Concrete Reinforcement

Introduction

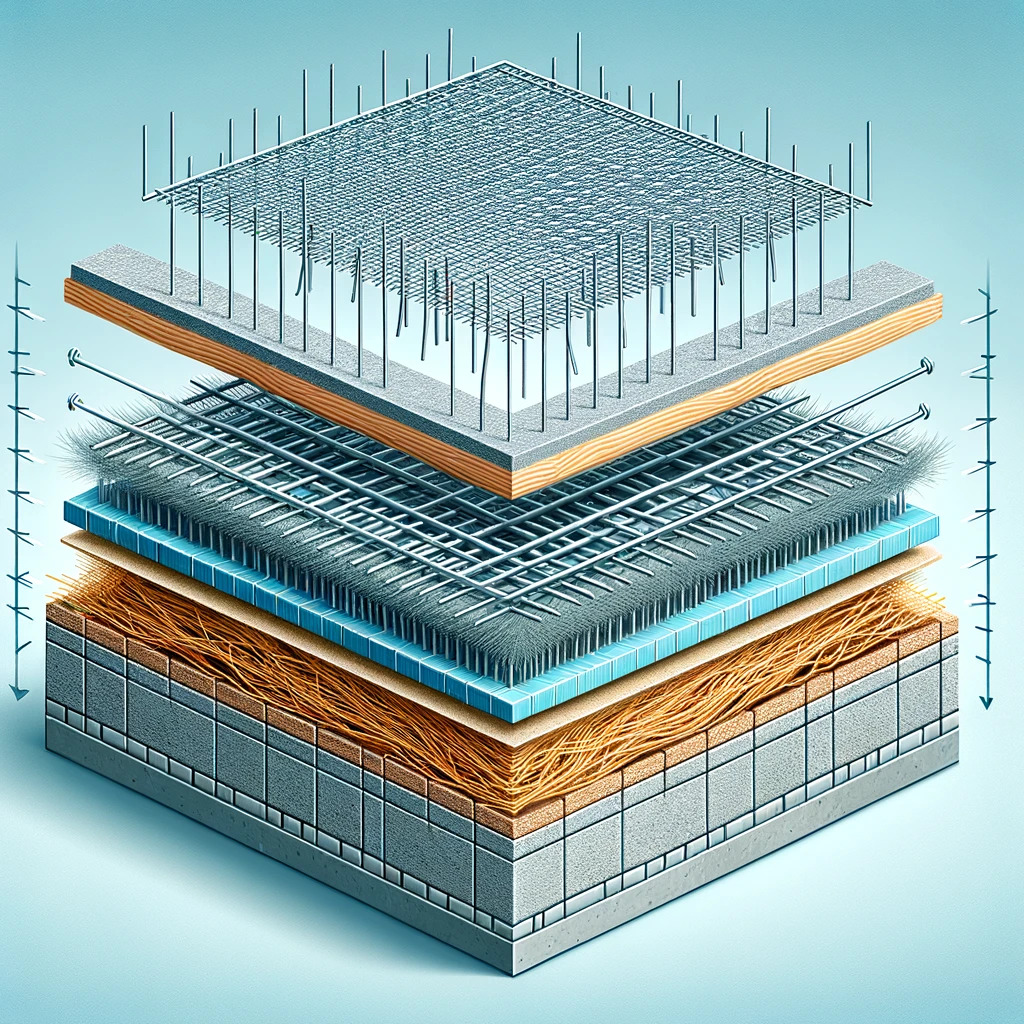

When it comes to reinforcing concrete, the strength and durability of the structure are paramount. Among the plethora of options available, wire mesh and fiber mesh stand out as two of the most popular methods. Both have their distinct advantages and applications, leading to the inevitable question: Are they truly interchangeable, or do certain scenarios favor one over the other? In this comprehensive exploration, brought to you by California Wire Products, we delve into the intricacies of fiber concrete vs wire mesh, comparing their characteristics, applications, and suitability for various projects to shed light on this query.Understanding Wire Mesh

Wire mesh, predominantly made of steel, serves as a stalwart in reinforcing concrete structures such as slabs, foundations, and driveways. It boasts high tensile strength, making it an excellent choice for supporting heavy loads. The availability and cost-effectiveness of wire mesh in concrete for large-scale projects further cement its popularity. However, its installation demands expertise to ensure effectiveness, and its susceptibility to rust presents a long-term challenge. Moreover, wire mesh’s rigidity makes it less suitable for thinner concrete sections, where flexibility and bonding might be more critical.Understanding Fiber Mesh

Fiber mesh presents a versatile alternative, with materials ranging from plastic and glass to steel fibers. This diversity makes fiber mesh adaptable for various applications, including thin slabs, overlays, and shotcrete. Its ease of mixing and placement, coupled with uniform distribution within the concrete, enhances its appeal. The corrosion resistance of fiber mesh is a significant advantage, especially in environments prone to moisture. However, its tensile strength might not rival thick wire mesh, and the cost considerations for large projects could deter some builders.Head-to-Head Comparison

To continue our debate on fiber concrete vs wire mesh, let us compare and highlight the distinct features of both:- Material: Wire mesh is steel-based, whereas fiber mesh uses a variety of materials including plastic, glass, and steel.

- Applications: Wire mesh is ideal for slabs, foundations, and driveways, while fiber mesh excels in thin slabs, overlays, and shotcrete.

- Tensile Strength: Wire mesh offers high tensile strength, essential for heavy loads, compared to the generally lower strength of fiber mesh.

- Installation Ease: Fiber mesh is easier to mix and place, offering a hassle-free application versus the installation expertise required for wire mesh in concrete.

- Cost: Wire mesh is cost-effective for large projects, while fiber mesh may incur higher costs.

- Corrosion Resistance: Fiber mesh offers superior corrosion resistance, a vital factor in its longevity.

- Suitability for Thin Sections: Fiber mesh’s flexibility makes it better suited for thin sections of concrete.

When to Choose Wire Mesh

Wire mesh, with its notable high tensile strength, is particularly suited for projects that demand the resilience to withstand heavy loads, such as in commercial buildings, industrial floors, and large infrastructure projects. Wire mesh in concrete ensures a structure’s integrity, especially in areas subjected to significant stress and strain. Choosing the right grade of wire mesh is vital, as different projects require different levels of strength and flexibility. Professional installation is equally important; improper placement can diminish its effectiveness, leading to potential structural failures. The correct installation of wire mesh involves careful planning and execution, ensuring that it is laid out uniformly and secured properly within the concrete matrix, enhancing the overall durability and load-bearing capacity of the structure.When to Choose Fiber Mesh

Fiber mesh is ideal for projects that benefit from its inherent properties of ease of use and excellent corrosion resistance, making it a standout choice for residential applications, including sidewalks, patios, and decorative concrete finishes. Its effectiveness in thin concrete sections makes it a go-to option for overlays and repair work, where maintaining the aesthetic appeal without compromising on strength is crucial. Selecting the right type of fiber—be it polypropylene, glass, steel, or a blend—is essential to achieve the desired results, as each type offers different benefits in terms of flexibility, strength, and bonding with the concrete. Proper mixing and distribution of the fiber mesh within the concrete mix are critical to ensure a uniform reinforcement that prevents cracking and enhances the surface durability, offering a practical solution for projects where traditional reinforcement methods might be cumbersome or impractical.Interchangeability

The decision between wire mesh and fiber mesh cannot be made lightly, as each offers unique advantages and limitations that must be considered in the context of the specific project at hand. The choice often hinges on a thorough understanding of the project’s structural requirements, the environmental conditions it will face, and the budget constraints. Projects exposed to harsh environments, for instance, might benefit more from the corrosion resistance offered by fiber mesh, whereas those requiring high tensile strength might find wire mesh to be indispensable. Consulting with construction and engineering professionals is crucial, particularly for complex or specialized projects. These experts can offer insights into the most appropriate choice of reinforcement based on years of experience and a deep understanding of material science, ensuring that the final structure is not only compliant with all relevant standards and regulations but also optimized for longevity, safety, and functional performance.Conclusion

The debate between fiber mesh vs wire mesh in concrete reinforcement is not about finding a one-size-fits-all solution but understanding the unique benefits and limitations of each option. By considering the specific needs of a project, builders and contractors can make informed decisions that ensure the longevity, safety, and aesthetic appeal of their structures. As always, seeking professional advice when in doubt can help navigate the complexities of choosing the right reinforcement method. California Wire Products remains a committed partner in providing quality wire mesh solutions for your construction needs, ensuring that your projects stand the test of time with the right blend of strength and flexibility. Call us at (951) 371-7730 for more information.FAQs

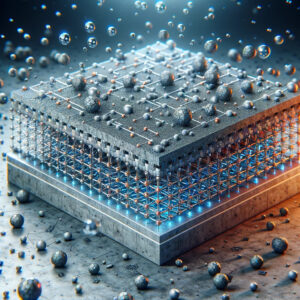

FAQ 1: Can I use both wire mesh and fiber mesh in the same concrete project? Yes, it’s possible to use both wire mesh and fiber mesh together in a single concrete project. This combination can offer the best of both worlds – the structural strength provided by wire mesh and the crack prevention benefits of fiber mesh. However, this approach should be carefully planned and discussed with a structural engineer to ensure compatibility and effectiveness based on the project’s specific requirements. FAQ 2: How does the environmental impact compare between wire mesh and fiber mesh? The environmental impact of wire mesh and fiber mesh varies based on their production processes and longevity. Wire mesh, being metal, has a significant carbon footprint due to mining and manufacturing processes. On the other hand, some types of fiber mesh, especially those made from recycled materials, can have a lower environmental impact. Additionally, the durability and corrosion resistance of fiber mesh can lead to a longer lifespan for concrete structures, potentially reducing the need for repairs and replacements. FAQ 3: Are there any innovations in concrete reinforcement that go beyond wire mesh and fiber mesh? The field of concrete reinforcement is continuously evolving, with new materials and technologies emerging. One such innovation is the development of nano-materials, such as carbon nanotubes and graphene, which can be added to concrete to enhance its strength and durability on a molecular level. Additionally, self-healing concrete, which incorporates certain bacteria that produce limestone to fill cracks as they form, represents a cutting-edge approach to increasing the longevity of concrete structures. These innovations offer promising alternatives for future construction projects, aiming for sustainability and enhanced performance.GET IN TOUCH

Contact us today to place your wire mesh order!