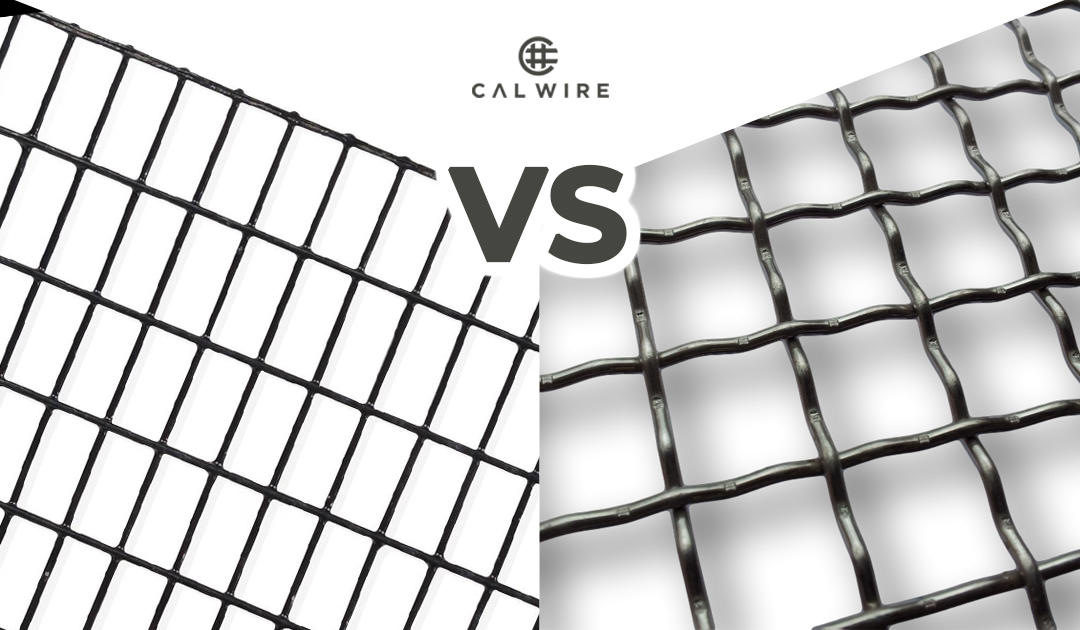

Woven vs. Welded Wire Mesh

There are unique advantages and disadvantages to each of them that are important to know. Here are some important things to know about these types of wire mesh:Woven wire mesh can change shape easily

Woven wire mesh tends to be much more flexible than welded ones. As a result, they are better at holding irregularly shaped, heavy contents.Woven wire mesh are often quite affordable

Woven mesh is much cheaper than welded ones. The specific difference in price depends on the type of metal used and other factors.Welded mesh are often quite rigid

It would be best to opt for a welded wire mesh instead of a woven one when looking for endurance and durability under specific circumstances that may bend the woven mesh over time.What are some examples of situations where each type would be useful?

Welded wire baskets have a wide range of applications such as racks, grates, guard screens, detention and security fencing, grills, and baskets. Woven wire mesh is used by numerous business owners in many different sectors of the economy. While there are many examples of situations when you might need welded wire baskets for your business, these are some of the most common ones:- Grates

- Display shelves

- Grills

- Baskets

- Fencing

- Air filtration

- Liquid filtration

Get in touch

If you’re interested in learning more about our products and how they’re made, you can get in touch with us for free. We’ll happily talk to you about our products, the manufacturing process, and the QC standards we consistently meet. So, give California Wire Products (Cal-Wire) a call today!GET IN TOUCH

Contact us today to place your wire mesh order!

Post A Comment