Wire Mesh Locker Solutions for Construction Site Storage

I. Introduction

Construction sites face many storage challenges, ranging from safeguarding expensive equipment to managing the personal belongings of the workforce. These sites require solutions that are secure, flexible, and easy to manage. Wire mesh lockers offer a stellar option for overcoming these common issues. California Wire Products, a leading provider in this field, offers mesh lockers that provide a robust answer to the critical needs of construction site storage.II. The Need for Secure Storage on Construction Sites

The dynamic and often exposed environments of construction sites elevate the necessity for secure storage systems. Tools, equipment, and personal items are susceptible to various risks, such as theft, damage from weather conditions, and misplacement. Theft, a significant concern on construction sites, can lead to costly delays and replacements. Furthermore, exposure to rain, dust, and other environmental factors can damage sensitive equipment. Additionally, retrieving tools can become time-consuming without proper organizational systems, thus hampering efficiency. Addressing these challenges is crucial for maintaining operational flow and safeguarding valuable assets.III. Benefits of Wire Mesh Lockers

Wire mesh lockers are uniquely designed to meet the challenging demands of construction sites. These lockers’ features provide specific benefits that enhance site efficiency, security, and management. Here’s an expanded look at each key advantage:Visibility

Wire mesh lockers excel in offering unmatched visibility. This feature is crucial on construction sites where quick verification of tools and equipment availability is necessary. Supervisors and workers can easily see the contents through the mesh without opening each locker, facilitating faster checks and reducing time wasted searching for items. This transparency helps monitor that all necessary tools are returned at the end of the day and helps quickly identify if something is missing or misplaced.Ventilation

The design of wire mesh lockers naturally incorporates excellent ventilation. This is particularly important in construction sites where tools and clothing may become damp. The open mesh allows air to circulate freely, quickly drying contents and preventing moisture buildup. This significantly reduces the risk of rust on metal tools and equipment and prevents the growth of mold on any stored fabrics, which can be crucial for maintaining the integrity and usability of construction materials and personal protective equipment.Security

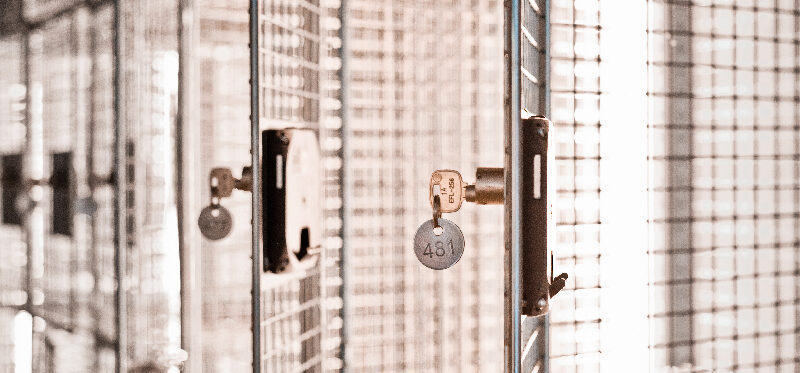

Security is paramount on construction sites, and wire mesh storage lockers address this need effectively. Made from robust, durable metal, these lockers have lockable features that protect against theft and unauthorized access. The strength of the material ensures that tools, equipment, and personal belongings are safely stored, providing peace of mind for workers and managers alike and helping to avoid the financial losses associated with theft and vandalism.Modularity

The modularity of wire mesh lockers is a significant advantage for construction sites, which often see changing needs as projects progress. These lockers can be easily configured and reconfigured to fit different spaces and accommodate varying amounts of equipment, tools, and personal items. This flexibility allows for optimal use of available space and can be adapted as the requirements of the construction site evolve, making them a cost-effective and adaptable storage solution.Durability

Designed to endure the harsh conditions typical of construction sites, wire mesh lockers are built to last. They resist wear and tear, standing up to the rough handling and heavy-duty use common in such environments. Their durability means they can withstand the elements and heavy use without compromising performance or security, making them a long-term investment for construction projects requiring reliable and sturdy storage solutions. Together, these features make wire mesh lockers an invaluable asset for improving the operational efficiency, security, and organization of construction sites, ultimately contributing to the smoother running and success of construction projects.IV. Types of Wire Mesh Lockers

Wire mesh lockers are versatile and come in various configurations to meet construction site storage needs. Each type caters to specific requirements, enhancing organization, security, and space utilization. Here’s a detailed look at each type:Full-Height Lockers

Full-height wire mesh lockers are particularly suited for storing larger items such as tools, machinery, and even bulky personal protective equipment. These lockers provide ample vertical space, ideal for securely accommodating tall items or stacking materials. The robust construction ensures that even heavy items can be stored without damaging the locker or its contents. Full-height lockers are essential for sites where large, valuable tools need secure storage that protects them from environmental exposure and potential tampering.Multi-Compartment Lockers

Multi-compartment wire mesh lockers are designed to address the personal storage needs of multiple workers at once. Each compartment can be individually locked, offering personal space for workers to store helmets, boots, personal items, and small tools. These lockers are particularly useful in maintaining organization and preventing the mix-up of personal belongings in busy site environments. The individual compartments promote responsibility and reduce the likelihood of personal items being misplaced or stolen, thereby enhancing worker satisfaction and site efficiency.Custom Solutions

Custom lockers offer a flexible solution for construction sites with unique layouts or specific storage needs that standard locker configurations cannot meet. Custom lockers can be designed to fit specific dimensions, incorporate varying compartment sizes, or include additional features like shelves or hanging rods. This adaptability ensures that every inch of available space can be effectively utilized, and storage solutions can be tailored to the site’s exact requirements, whether it’s accommodating irregularly shaped equipment or fitting into an unconventional space. These varied types of wire mesh lockers ensure that regardless of a construction site’s specific needs or challenges, storage options are available to keep tools, equipment, and personal items organized, secure, and easily accessible. This variety allows project managers and site planners to choose the right storage configurations to optimize site functionality and worker convenience.V. Implementing Wire Mesh Locker Solutions

Implementing wire mesh lockers on construction sites involves a systematic approach to ensure that the solutions provided are effective and efficient. Here’s a closer examination of each implementation step:Planning

The planning phase is critical in determining the success of wire mesh locker implementations. It involves a detailed site assessment to understand the specific storage needs and the available space. This step should include consultations with site managers and workers to gather insights on what tools, equipment, and personal items need storage. Additionally, evaluating the site layout helps decide where lockers should be placed to maximize accessibility and convenience without obstructing work areas. Accurate planning ensures that the selected lockers will adequately meet the site’s demands, providing enough space and the right type of security.Installation

Proper installation of wire mesh lockers is essential to ensure they are both secure and functionally optimal. This often includes anchoring the lockers to stable surfaces like floors or walls to prevent tipping or shifting, which could lead to injuries or security breaches. It is also important to position lockers in a way that they are easily accessible but do not interfere with the site’s daily operations. Sometimes, installation might require adjustments or additional fittings to cater to site-specific conditions, such as uneven grounds or restricted spaces.Maintenance

Regular maintenance is crucial to keeping wire mesh lockers in good working condition and extending their lifespan. Scheduled inspections should check for issues such as rust, loose bolts, or damaged locks and hinges. Keeping the lockers clean and free from debris not only helps maintain their functionality but also ensures they remain presentable and safe to use. Maintenance practices should also include immediate repairs or replacements of faulty parts to prevent security risks or further damage.VI. Choosing the Right Wire Mesh Locker Provider

Selecting an appropriate provider for wire mesh storage lockers involves several considerations that can significantly impact the effectiveness of the storage solution:Customization Options

A provider that offers customizable locker solutions can be precious, especially for sites with unique requirements. This flexibility allows construction sites to tailor their storage solutions to fit specific dimensions, incorporate special features, or address unique challenges of the site.Material Quality

The quality of materials used to construct wire mesh lockers determines their durability and security. High-grade materials can withstand the harsh conditions of construction sites and provide dependable long-term storage. Providers who source premium materials should be prioritized to ensure the lockers are robust and resistant to environmental and mechanical wear.Customer Service

Reliable customer service is crucial for resolving any issues that might arise during or after the installation of the lockers. Providers with a strong customer support team can offer guidance during the selection process, assist with installation tips, and help resolve any maintenance issues quickly, minimizing downtime on the site. When selecting a provider, conducting a survey or reviewing comparisons of leading manufacturers or providers in the market can help determine who best meets these criteria. This research will help ensure that the chosen provider can deliver high-quality, reliable wire mesh lockers suitable for the specific demands of the construction site.VII. Conclusion

Wire mesh lockers are more than just storage units; they are a critical component in enhancing construction site security, efficiency, and organization. By investing in these robust, versatile, and secure storage solutions, site managers can significantly mitigate risks associated with theft and damage while boosting operational efficiency. For a tailored solution that precisely fits your site’s unique demands, consider consulting with a seasoned professional like California Wire Products, who can conduct a comprehensive storage needs assessment. Call us at (951) 371-7730 for more information.FAQs

FAQ 1: What customization features are available for wire mesh lockers? Answer: Our wire mesh lockers can be customized with various features to suit your specific needs. Options include adjustable shelving, different lock types (e.g., padlocks, combination locks, key locks), and choices in colors and finishes to match your company branding or to designate different areas or purposes on your construction site. FAQ 2: How do wire mesh lockers contribute to sustainability on construction sites? Answer: Wire mesh lockers are a sustainable storage option because they are made from durable and recyclable materials. Their longevity reduces the need for frequent replacements, and their ventilated design decreases the energy and resources needed to maintain tools and equipment in good condition by naturally preventing moisture buildup and corrosion. FAQ 3: Are wire mesh lockers suitable for outdoor areas of a construction site? Answer: Yes, wire mesh lockers are designed to be robust and weather-resistant, making them ideal for both indoor and outdoor use on construction sites. They are treated with weatherproof coatings to resist rain and UV damage, ensuring that they provide secure and reliable storage in various environmental conditions.GET IN TOUCH

Contact us today to place your wire mesh order!