Introduction

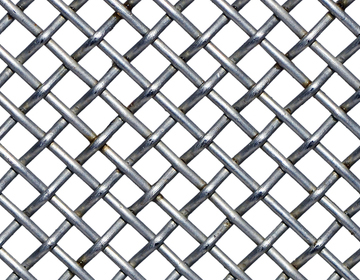

In today’s dynamic and evolving industries, the need for specific, high-performance materials is greater than ever. One such material that continues to stand out for its versatility and wide range of applications is metal mesh. While standard metal mesh products may suffice for some projects, many industries now realize the benefits of opting for personalized wire mesh. These custom solutions allow for precise tailoring to meet unique project specifications, ensuring a perfect fit every time.

With the rising demand for tailored solutions, companies like California Wire Products are leading the way in providing various wire mesh options. Whether you’re working on an architectural project that requires a specific aesthetic touch or an industrial application where durability and strength are paramount, customized wire mesh delivers the versatility needed to meet your exact requirements. By choosing customized solutions, you guarantee your project’s success, ensuring that every element is perfectly aligned with your goals.

Key industry standards for wire mesh include ASTM E2016 for woven wire cloth and ASTM A740 for welded wire mesh, which define specifications for mesh dimensions, materials, and tolerances. Compliance with these standards ensures quality and durability across various applications. Additionally, ISO 9044 provides international guidelines for wire mesh materials and performance requirements.