The Ultimate Guide to Reinforcing Concrete Driveways with Wire Mesh

Introduction

Concrete driveways are a favorite among homeowners for their durability and sleek look. However, just like any other material, concrete can develop cracks and shift over time. To keep your driveway strong and long-lasting, reinforcement is key. One popular reinforcement method is using wire mesh in concrete. In this blog, we’ll explore why reinforcing your concrete driveway is so important, the benefits of using wire mesh, and some tips from the experts at California Wire Products.1. Understanding Concrete Driveways

Basics of Concrete as a Material

Concrete is a composite material composed of cement, water, and aggregates like sand and gravel. When mixed, these components form a paste that hardens over time, creating a robust and durable surface. Concrete’s versatility makes it a favored material for various construction projects, including driveways.Typical Applications and Benefits of Concrete Driveways

Concrete driveways are known for their strength, longevity, and low maintenance requirements. They can withstand heavy loads, making them ideal for residential and commercial properties. Concrete driveways can be customized with various finishes and colors to enhance curb appeal.Common Issues Faced by Concrete Driveways

Despite their durability, concrete driveways can develop problems such as cracking, shifting, and surface wear. These issues often arise from factors like ground movement, temperature fluctuations, and heavy traffic loads. Reinforcement helps mitigate these problems by adding extra support to the concrete structure.2. The Role of Reinforcement in Concrete

Explanation of Why Reinforcement is Necessary

Reinforcement is crucial in concrete structures to improve their tensile strength and prevent cracking. Concrete is strong in compression but weak in tension. Reinforcement materials like rebar, wire mesh, and fiber mesh help distribute loads and resist tensile forces, extending the lifespan of concrete driveways.Different Types of Reinforcement Materials

- Rebar: Steel bars placed in a grid pattern within the concrete.

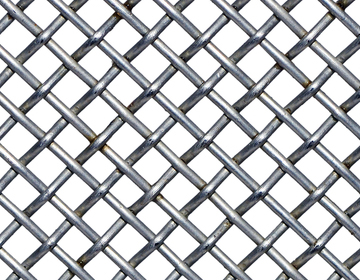

- Wire Mesh: A grid of thin steel wires welded together.

- Fiber Mesh: Synthetic fibers mixed into the concrete.

Comparison of Reinforcement Methods

- Rebar and Concrete: Offers high tensile strength but can be labor-intensive to install.

- Wire Mesh and Concrete: Provides uniform reinforcement and is easier to handle.

- Fiber Mesh and Concrete: Distributes reinforcement throughout the concrete mix but may not offer the same strength as steel options.

3. What is Wire Mesh?

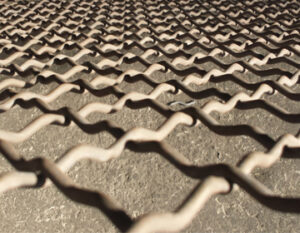

Description and Types of Wire Mesh

Wire mesh, also known as welded wire fabric, consists of a grid of thin steel wires welded at their intersections. It comes in various sizes and gauges, with different spacing patterns to suit specific applications. The size of wire mesh for concrete depends on multiple factors.How Wire Mesh is Manufactured and Used in Construction

Wire mesh is manufactured by welding steel wires at their intersections to form a grid pattern. It is typically sold in rolls or sheets and is laid into the concrete during the pouring process to provide reinforcement.Benefits of Using Wire Mesh in Concrete Driveways

Wire mesh offers several advantages, including increased strength, ease of installation, and cost-effectiveness. It helps distribute loads evenly, reducing the risk of cracks and enhancing the overall durability of the driveway.4. Advantages of Using Wire Mesh in Concrete Driveways

Increased Strength and Durability

Wire mesh in concrete enhances the structural integrity of concrete driveways, making them more resistant to heavy loads and environmental stressors.Prevention of Cracks and Distribution of Load

Wire mesh distributes tensile forces across the concrete surface to help prevent cracks and reduce the risk of shifting or settling.Cost-Effectiveness and Ease of Installation

Wire mesh for concrete is relatively inexpensive compared to other reinforcement options and is easier to install, making it a popular choice for both DIY enthusiasts and professionals.Long-Term Maintenance Benefits

Reinforced concrete driveways require less maintenance over time, as the added strength helps prevent common issues like cracking and surface wear.5. Potential Drawbacks of Wire Mesh

Initial Cost Considerations

While wire mesh is cost-effective, it does add to the overall expense of a concrete driveway project. Homeowners should consider their budget and weigh the benefits against the initial costs.Installation Challenges

Proper wire mesh installation requires precision to ensure it is correctly positioned within the concrete. Incorrect placement can reduce its effectiveness and lead to potential issues.Possible Alternatives to Wire Mesh

- Rebar: Offers higher tensile strength but is more labor-intensive.

- Synthetic Fibers: Provide uniform reinforcement but may not match the strength of steel options.

6. Factors to Consider When Deciding on Wire Mesh

Climate and Environmental Conditions

Consider the local climate and environmental factors, such as freeze-thaw cycles and soil conditions, which can impact the performance of reinforced concrete.Traffic Load and Usage Patterns

Assess the expected traffic load and usage patterns of the driveway to determine the appropriate level of reinforcement needed.Soil Conditions and Driveway Size

The type of soil and the driveway size can influence the reinforcement choice. For example, expansive soils may require additional reinforcement to prevent shifting.Budget and Long-Term Goals

Evaluate your budget and long-term goals for the driveway. While reinforcement adds to the initial cost, it can significantly save repairs and maintenance over time.7. DIY vs. Professional Installation

Pros and Cons of Installing Wire Mesh Yourself

- Pros: Cost savings, personal satisfaction, and control over the project.

- Cons: Requires knowledge and skill, risk of improper installation, and potential safety hazards.

Steps Involved in a DIY Installation

- Prepare the site by removing old concrete and leveling the ground.

- Lay a gravel base and compact it.

- Position the wire mesh within the formwork, ensuring proper spacing.

- Pour the concrete and ensure it fully encapsulates the wire mesh.

- Finish the surface and allow it to cure.

When to Consider Hiring a Professional

Hiring a professional can ensure the job of installing welded wire mesh in concrete is done correctly and safely for complex projects or if you need clarification on the installation process.Conclusion

Reinforcement is a crucial component in constructing durable and long-lasting concrete driveways. Wire mesh offers a cost-effective and efficient solution to enhance the strength and performance of concrete structures. Homeowners can make informed decisions that best suit their needs and conditions by understanding the benefits and potential drawbacks of wire mesh in concrete. Whether opting for a DIY approach or hiring a professional, reinforcing your concrete driveway with wire mesh from California Wire Products can provide significant long-term benefits. Call us at (951) 371-7730 for more information.FAQs

1. Can wire mesh be used in all types of concrete projects? A: Yes, wire mesh can be used in a variety of concrete projects beyond driveways, including patios, sidewalks, and foundations. Its versatility makes it a popular choice for reinforcing concrete structures to enhance their durability and resistance to cracking. 2. How do I determine the right size of wire mesh for my concrete driveway? A: The size of wire mesh for concrete driveways depends on the specific requirements of your project, such as the thickness of the concrete and the expected load. Consulting with a supplier like California Wire Products or a professional contractor can help you choose the appropriate gauge and spacing for optimal reinforcement. 3. Is wire mesh environmentally friendly? A: Wire mesh is made from steel, which is recyclable. Using wire mesh in concrete projects can contribute to sustainability efforts by reducing the need for frequent repairs and replacements, thereby minimizing waste and resource consumption over time.GET IN TOUCH

Contact us today to place your wire mesh order!