Introduction

Industrial filtration is an essential process across various sectors, from manufacturing and chemical processing to food production and pharmaceuticals. Cleanliness, precision, and efficiency are paramount in these environments, where even the smallest particles can compromise product quality or system performance. One of the most effective solutions for achieving reliable separation of solids from liquids or gases is the stainless steel mesh screens.

Designed for strength, durability, and accuracy, these filtration components are integral to modern filtration systems. As a leading manufacturer and supplier, California Wire Products is committed to producing high-performance filtration mesh screens that meet the rigorous demands of industrial operations. With decades of experience and a focus on custom fabrication, California Wire Products ensures that clients receive filtration solutions engineered for long-lasting performance and value.

What Are Stainless Steel Mesh Screens?

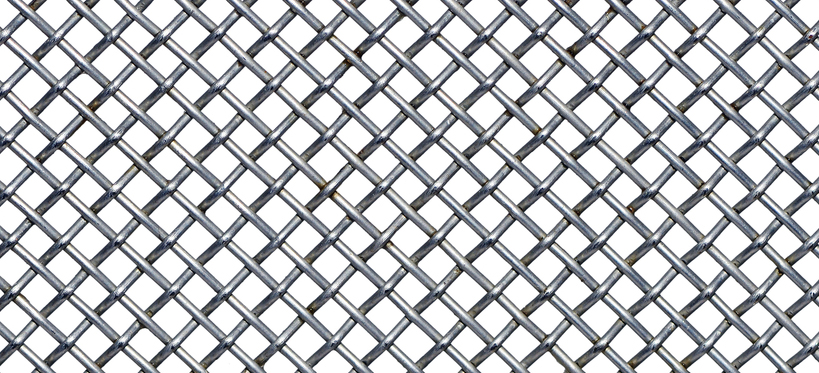

Stainless steel mesh screens are woven or welded wire mesh panels made from high-grade stainless steel wires. These screens serve as a physical barrier that allows liquids or gases to pass through while capturing unwanted solids. Their precise structure makes them suitable for various industrial processes requiring consistent filtration.

Common materials used in their construction include 304 stainless steel, prized for its general corrosion resistance and affordability, and 316 stainless steel, which offers enhanced resistance to acids, chlorides, and other harsh chemicals. Both types are used widely in woven wire mesh filtration systems due to their strength and resistance to wear.

The effectiveness of these mesh screens is determined largely by the mesh size—the number of openings per linear inch—and wire diameter, both of which affect the open area and filtration capability. For instance, fine mesh screens with high mesh counts are ideal for capturing small particles, while coarse meshes are suited for pre-filtration or heavy solids.

Key Benefits of Stainless Steel Mesh Screens for Filtration

1. Durability and Strength

One of the standout qualities of stainless steel wire mesh is its exceptional strength and resistance to mechanical stress. These mesh screens withstand exposure to high pressure, caustic substances, and abrasive materials without degrading. The inherent corrosion-resistant mesh properties of stainless steel make it ideal for continuous use in aggressive environments such as chemical plants, offshore platforms, and wastewater facilities.

Additionally, the long lifespan of stainless steel mesh screens reduces the need for frequent replacements, which saves time and operational costs.

2. High Precision Filtration

A stainless steel mesh filter provides uniform openings that ensure consistent particle retention, a critical factor in applications requiring accuracy—such as pharmaceutical manufacturing or microelectronics. Mesh counts can range from as low as 4 mesh (coarse) to over 400 mesh (ultra-fine), allowing users to customize filtration levels based on their exact needs.

3. Easy Maintenance and Cleaning

Unlike many synthetic filter alternatives, filtration mesh screens made from stainless steel are reusable and easy to clean. They can be backwashed, pressure washed, or chemically cleaned without compromising their structural integrity. This feature is particularly useful in industries where filters must be changed or cleaned frequently, such as food processing or beverage production.

4. Temperature Resistance

Stainless steel performs exceptionally well in extreme temperatures, both hot and cold. Whether used in cryogenic applications or high-heat processes like metal fabrication and oil refining, stainless steel mesh maintains its performance and shape. This makes it an ideal solution for filtration systems exposed to fluctuating or extreme conditions.

5. Hygienic and Food-Grade Options

In industries where sanitation is non-negotiable, such as food and pharmaceutical production, stainless steel mesh provides a non-reactive and easy-to-clean surface. FDA-compliant and NSF-rated materials are available for applications that demand hygienic filtering, making stainless steel wire mesh the go-to choice for environments where contamination control is critical.

Common Industrial Applications

The versatility and durability of stainless steel mesh screens make them indispensable across a wide array of sectors:

- Water and Wastewater Treatment: Mesh screens help remove suspended solids, algae, and debris from both municipal and industrial water systems.

- Oil and Gas Filtration: Used in upstream, midstream, and downstream operations to separate particulates from hydraulic fluids, fuel, and drilling mud.

- Chemical Processing: Essential for filtering corrosive liquids and protecting sensitive components from particle contamination.

- Food and Beverage Production: Utilized for straining, sieving, and particle separation in processes involving liquids like juice, dairy, and brewing.

- Pharmaceutical Manufacturing: Ensures contaminant-free products by filtering out particles during production and packaging.

- Mining and Aggregate Filtration: Separates fine sediments and debris from valuable minerals and materials in large-scale operations.

Each of these industries benefits from the adaptability and resilience of woven wire mesh filtration systems designed for high-load performance and accuracy.

Why Choose Stainless Steel Mesh from California Wire Products?

When it comes to sourcing a stainless steel mesh filter, not all products are created equal. California Wire Products offers a comprehensive range of filtration mesh screens designed to meet the toughest industrial challenges.

What sets California Wire Products apart:

- Custom Fabrication: From one-off prototypes to large production runs, we manufacture filters to your exact specifications.

- Material Variety: We offer 304, 316, and specialty alloys tailored for chemical compatibility, strength, or sanitation.

- Range of Mesh Sizes and Wire Diameters: With our broad selection, we provide filtration options for everything from bulk solids to fine particulates.

- Expert Engineering Support: Our team provides technical guidance to help clients choose the best stainless steel wire mesh for their needs.

- Trusted Reputation: Serving industries across California and the U.S., we are known for reliability, precision, and innovation.

How to Select the Right Mesh Screen for Your Application

Choosing the ideal mesh screen for your system involves several important factors:

- Mesh Count: Determines the level of filtration precision (higher counts for finer filtration).

- Wire Diameter: Influences strength and flow resistance.

- Open Area: The percentage of mesh that is open impacts throughput and efficiency.

- Material Grade: Different alloys are better suited for different chemicals, temperatures, and wear conditions.

It’s also essential to consider the type of filtration (surface vs. depth), the nature of the contaminants, and whether cleaning or backwashing will be required. Working with a trusted supplier like California Wire Products ensures you receive not just a product, but a complete filtration solution tailored to your operation.

Conclusion

Stainless steel mesh screens are foundational to effective, efficient, and long-lasting industrial filtration systems. Their durability, precision, and versatility make them the material of choice in applications ranging from water treatment and food processing to chemical and pharmaceutical manufacturing. With features like corrosion resistance, reusability, and high-temperature tolerance, these filters are engineered to perform under pressure.

At California Wire Products, we specialize in delivering custom stainless steel mesh filters and woven wire mesh filtration solutions that meet the unique needs of modern industry. Our commitment to innovation, material quality, and client satisfaction makes us a leading partner for industrial filtration systems.

Contact California Wire Products at +1 951-371-7730 to learn more about our filtration mesh screens and how we can support your business with durable, high-performance stainless steel solutions.

1. Can stainless steel mesh screens be used for filtering gases as well as liquids?

A: Yes. Stainless steel mesh screens are highly effective for gas filtration, especially in HVAC systems, air purification, and industrial exhaust applications. Their strength and resistance to high temperatures make them ideal for removing airborne particles without degrading under pressure or heat.

2. Are there eco-friendly advantages to using stainless steel mesh screens?

A: Absolutely. Unlike disposable synthetic filters, stainless steel mesh screens are reusable and recyclable. Their long service life reduces waste, and their ability to be cleaned and reused supports sustainable practices in industrial operations.

3. What customization options are available for stainless steel mesh screens?

A: Stainless steel mesh screens can be tailored in terms of mesh count, wire thickness, weave pattern (plain, twill, Dutch), frame type, and even screen shape or layering. This flexibility ensures compatibility with unique systems and enhances filtration efficiency for specialized needs.