The Comprehensive Guide to Using Concrete Wire Mesh

Introduction

Concrete structures are a cornerstone of modern construction, providing strength and durability to buildings, bridges, roads, and more. However, concrete alone isn’t always sufficient to withstand the various stresses it encounters. Reinforcement is crucial in ensuring the longevity and robustness of concrete structures. One of the most effective reinforcement options available today is concrete wire mesh. At California Wire Products, we specialize in providing high-quality wire mesh rolls that enhance the integrity and lifespan of your concrete projects.Section 1: Understanding Concrete Reinforcement

Concrete is exceptionally strong in compression but relatively weak in tension. This inherent limitation necessitates the use of reinforcement materials that can compensate for this weakness. The primary purpose of reinforcement is to improve the tensile strength of concrete, making it more resilient to cracks and structural failure. Without reinforcement, concrete structures would be prone to cracking under tensile stress, leading to potential structural failures over time. There are several types of reinforcement materials used in concrete construction:-

Steel Rebar

-

Fiber Reinforcement

-

Concrete Wire Mesh Rolls

Section 2: What Are Wire Mesh Rolls?

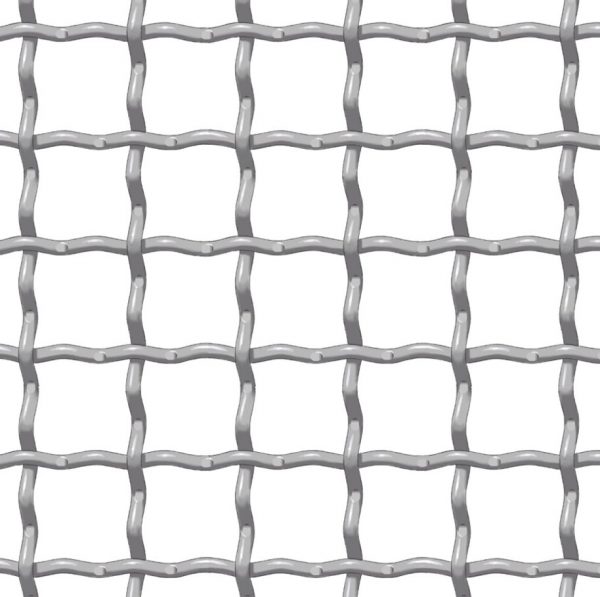

Wire mesh rolls are made from interconnected steel wires, forming a grid pattern that provides additional strength to concrete. These rolls are designed to distribute loads and stresses evenly across the concrete surface, enhancing its overall structural integrity. Wire mesh rolls come in two main types:-

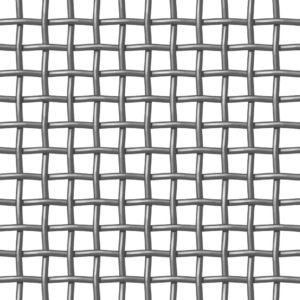

Welded Wire Mesh

-

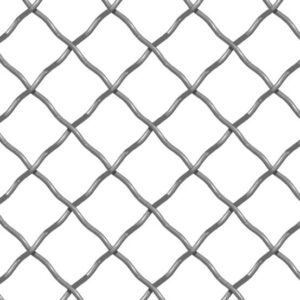

Woven Wire Mesh

Section 3: Benefits of Using Wire Mesh Rolls

Using a concrete wire mesh roll in construction offers numerous advantages:-

Enhanced Structural Integrity

-

Distribution of Load and Stress

-

Prevention of Cracking and Surface Damage

-

Ease of Installation

-

Cost-Effectiveness

Section 4: Applications of Wire Mesh Rolls in Concrete Structures

Wire mesh rolls are used across various types of construction projects, including:-

Residential Buildings

-

Commercial Structures

-

Industrial Applications

-

Infrastructure Projects

Section 5: Installation Process of Wire Mesh Rolls

Proper installation is key to maximizing the benefits of wire mesh rolls. The process involves:-

Preparing the Site and Foundation

-

Placing the Wire Mesh

-

Securing and Overlapping Mesh Sections

-

Pouring and Curing the Concrete

Section 6: Best Practices and Tips

To ensure the effectiveness of concrete wire mesh rolls, follow these best practices:-

Choosing the Right Type and Size

-

Ensuring Proper Installation and Spacing

-

Maintenance and Inspection Tips

Conclusion

Wire mesh rolls play a critical role in enhancing the strength and durability of concrete structures. They offer a reliable, cost-effective reinforcement solution that can be tailored to various applications. As construction technology evolves, wire mesh rolls are likely to expand, incorporating new innovations and techniques. For any upcoming projects, consider concrete wire mesh from California Wire Products to achieve more robust and long-lasting concrete structures. With their ease of installation, cost-effectiveness, and numerous benefits, wire mesh rolls are an excellent choice for reinforcing concrete in various construction projects. Call us at (951) 371-7730 for more information.FAQs

FAQ 1: How do wire mesh rolls compare to traditional rebar in concrete reinforcement? A: Wire mesh rolls offer a more uniform reinforcement across the concrete surface compared to rebar, making them ideal for preventing surface cracks and distributing loads evenly. They are also easier and quicker to install, which can save time and labor costs. FAQ 2: Can wire mesh rolls be used for DIY home projects? A: Absolutely! Wire mesh rolls are versatile and user-friendly, making them suitable for various DIY home projects like driveways, patios, and small-scale concrete slabs. They provide excellent reinforcement without the complexity of traditional rebar. FAQ 3: What should I consider when choosing the size and type of wire mesh roll for my project? A: When selecting wire mesh rolls, consider the specific requirements of your project, including load-bearing needs and the type of stress the concrete will endure. Different projects may require varying mesh sizes and types, so consulting with a supplier like California Wire Products can help ensure you choose the right mesh for optimal performance.GET IN TOUCH

Contact us today to place your wire mesh order!