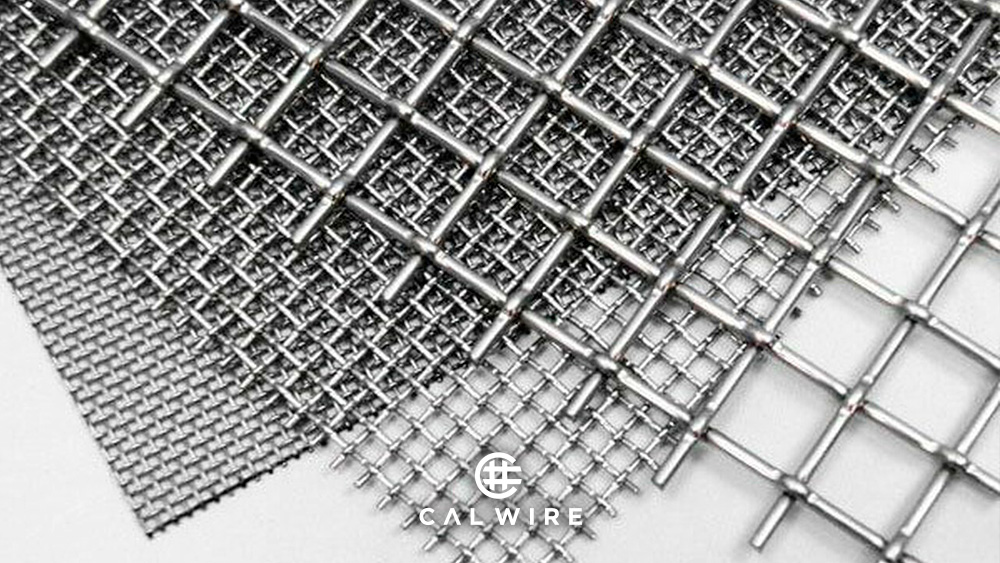

Different Types of Wire Mesh

Wire mesh is used widely in architecture and construction, not just for aesthetic enhancements but also to improve the integrity and security of construction projects. Some of the benefits offered by wire meshes include enhancing aesthetic appeal, offering privacy and security, keeping pests and animals out, regulating temperature regulation, and more. It is safe to assume that there are different types of wire mesh to meet specific needs, each with so many benefits. Not every wire mesh is perfect for every project; some have very particular demands such as weight, finish, strength, and more. The determining factor always ends up being the material it is made from, the finish, and the pattern. Contractors, builders, and architects must know where to buy different types of wire mesh and which one to buy to make sure their project flows smoothly.Different Types of Wire Mesh

The wire mesh’s “finish” and material used is what defines a majority of its properties. These include:Wire Mesh Welded AFTER Galvanization

There are two different types of galvanized wire mesh; welded or woven. The names are pretty self-explanatory, i.e., the galvanized welded wire mesh is welded at horizontal and vertical points. These are coated with zinc but exposed from welding points. The most common use of these wire meshes is around gardens, commercial stores, or other public areas.Wire Mesh Woven AFTER Galvanization

This wire mesh isn’t welded, and therefore, the zinc coating isn’t burnt, meaning that the mesh is safe from rust. These are lightweight, flexible, and have a much longer life. However, these are slightly more expensive as well.

The most common use of these wire meshes is when securing facilities or wildlife boundaries.

Wire Mesh Welded BEFORE Galvanization

Here, the steel or iron wire mesh is first welded, after which it gets dipped into molten zinc, thoroughly sealing the wire structure. It protects them from rust and corrosion and has a longer life – even when exposed to extreme temperatures. Naturally, this wire mesh will be more expensive, but it is well worth the investment in the long run. This wire mesh finds the most common use of wire mesh on animal cages, using wire mesh on ships (because of their saltwater resistance), and other humid or damp-place usage.Vinyl Coated Wire Mesh

These wire meshes are coated with PVC or polyester after getting welded or woven. These meshes can easily be given any color the client wants, but the most common ones are black and green because of their ability to blend in with the environment. The coating seals the wire mesh, thus protecting it from rust and corrosion. These meshes can be used anywhere easily and are available in different quality grades. These aren’t usually available in stores and need to be fabricated.Stainless Steel/Alloy Wire Meshes

These meshes are known mainly for their specialized nature and long life. These wire meshes are often used in coastal areas and boast long lives, even after saltwater and UV exposure. Of course, these are the most expensive option out there, but they are well worth it in the long run, particularly stainless steel meshes. Other alloys can be used as well, such as copper alloys. When getting wire meshes made to order, there are a lot of considerations to make. If you would like to learn more about the fabrication process, where to buy different types of wire meshes, and the utility offered by other materials, please don’t hesitate to California Wire Products (Cal-Wire) and get a FREE quote!GET IN TOUCH

Contact us today to place your wire mesh order!

Post A Comment